Stone diamond tools play a crucial role in various industries, particularly in stone fabrication and construction. Among the wide range of diamond tools available, the continuous turbo cup wheel stands out as a versatile and efficient tool for grinding, shaping, and polishing stone surfaces. In this article, we will explore the features, applications, advantages, and maintenance tips for the continuous turbo cup wheel, providing a comprehensive overview of this essential tool.

1. What is a Continuous Turbo Cup Wheel?

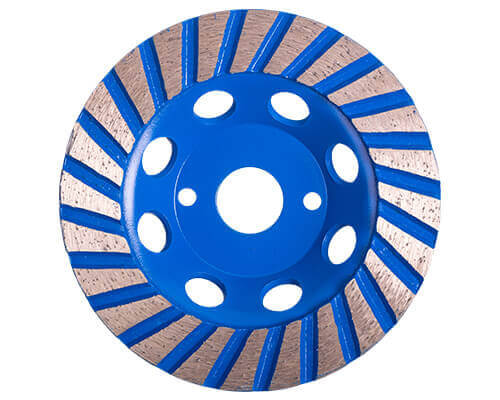

A continuous turbo cup wheel is a specialized diamond tool consisting of a circular steel core embedded with high-quality diamond segments. Unlike segmented cup wheels with gaps between the segments, the continuous turbo cup wheel features a continuous rim with tightly packed diamond segments, offering several benefits in terms of cutting performance and durability.

2. Features and Design of Turbo Cup Wheel:

The continuous turbo cup wheel is designed with the following key features:

a. Continuous Rim:

The continuous rim provides smooth and precise cutting, grinding, and polishing action, allowing for efficient material removal.

b. Turbo Segments:

The turbo-style diamond segments are designed with grooves or slots that enhance cooling and dust removal, preventing overheating and clogging during prolonged use.

c. Steel Core:

The steel core provides stability and strength to the cup wheel, ensuring its durability and resistance to heavy-duty applications.

3. Applications of continuous turbo cup wheel:

The continuous turbo cup wheel finds extensive application in various tasks involving stone, concrete, masonry, and other hard materials. Some common applications include:

a. Grinding and Shaping:

The cup wheel is used for grinding and shaping stone surfaces, such as countertops, floors, and edges, to achieve a smooth and even finish.

b. Surface Preparation:

It is employed for surface preparation before applying coatings, adhesives, or other finishes to ensure proper adhesion and a clean substrate.

c. Material Removal:

The cup wheel efficiently removes excess material, such as epoxy or glue residues, paint, or other coatings, from stone surfaces.

d. Polishing:

By utilizing specific diamond grit sizes and polishing pads, the continuous turbo cup wheel can also be used for polishing and achieving a glossy finish on stone surfaces.

4. Advantages of the Continuous Turbo Cup Wheel:

The continuous turbo cup wheel offers several advantages over other diamond tools:

a. Fast Material Removal:

The continuous rim design, combined with the turbo segments, enables rapid material removal, increasing efficiency and reducing project time.

b. Smooth and Precise Cutting:

The continuous rim ensures a clean and precise cut, reducing the need for additional smoothing or finishing work.

c. Versatility:

The continuous turbo cup wheel is compatible with various materials, making it a versatile tool for different applications in stone fabrication, construction, and renovation.

d. Durability:

The high-quality diamond segments and robust steel core contribute to the cup wheel’s durability, allowing it to withstand heavy-duty use and extended operational life.

5. Maintenance and Safety Tips:

To ensure optimal performance and longevity of the continuous turbo cup wheel, follow these maintenance and safety guidelines:

a. Proper Mounting:

Ensure the cup wheel is correctly mounted and securely tightened to the power tool or grinder.

b. Cooling and Lubrication:

Regularly cool the cup wheel during operation to prevent overheating, and use water or appropriate coolant to reduce friction and improve cutting efficiency.

c. Safe Operation:

Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a dust mask, to protect against potential hazards and airborne particles.

d. Regular Cleaning:

After each use, clean the cup wheel to remove debris and residue, ensuring optimal cutting performance and preventing clogging.

The continuous turbo cup wheel is a valuable tool for professionals in stone fabrication, construction, and related industries. Its innovative design, efficient material removal, and versatility make it an indispensable asset for various applications. By following proper maintenance and safety guidelines, users can maximize the cup wheel’s performance, durability, and overall effectiveness in their projects.

6. Grit Sizes:

Continuous turbo cup wheels are available in different diamond grit sizes, ranging from coarse to fine. The selection of the appropriate grit size depends on the specific application and the desired finish. Coarse grits (such as 30 or 40) are ideal for initial material removal and shaping, while finer grits (such as 100 or 200) are suitable for smoothing and polishing tasks.

7. Wet and Dry Cutting:

Continuous turbo cup wheels can be used for both wet and dry cutting operations. Wet cutting involves using water or a coolant to reduce heat and friction during operation, while dry cutting is performed without any liquid. Wet cutting is preferred for tasks that generate a significant amount of dust or require improved cooling, while dry cutting offers convenience and is suitable for smaller projects.

8. Compatibility:

Continuous turbo cup wheels are designed to be compatible with various power tools and grinders, including angle grinders and stone polishers. It is essential to ensure that the cup wheel’s size and arbor hole match the specifications of the tool being used to ensure a secure and proper fit.

9. Choosing the Right Cup Wheel:

When selecting a continuous turbo cup wheel, consider factors such as the material to be worked on, the desired finish, and the specific application. Different cup wheels are designed for different materials, such as concrete, granite, marble, or engineered stone. Additionally, consider the intensity of the task, as heavy-duty applications may require cup wheels with more durable diamond segments and a robust steel core.

10. Pro Tips for Optimal Performance:

Here are a few additional tips to enhance the performance and longevity of your continuous turbo cup wheel:

a. Use light pressure:

Apply gentle and consistent pressure when using the cup wheel to avoid unnecessary wear and tear on the tool.

b. Monitor the wear of diamond segments:

Keep an eye on the condition of the diamond segments. As they wear down, the cutting efficiency decreases. Replace the cup wheel when the segments become too worn to maintain optimal performance.

c. Work in even passes:

When grinding or polishing large surfaces, divide the area into smaller sections and work in even passes to ensure a consistent finish and prevent uneven material removal.

d. Follow the manufacturer’s instructions:

Always refer to the manufacturer’s guidelines regarding operating speeds, recommended coolant usage, and any specific instructions for your cup wheel model.

The continuous turbo cup wheel is a versatile and effective tool for stone fabrication, offering efficient material removal, precise cutting, and a range of applications. By selecting the appropriate cup wheel, following maintenance guidelines, and using proper techniques, professionals can achieve outstanding results in their stone-related projects while ensuring the longevity and performance of their continuous turbo cup wheel.

| Diameter | Bore | Segment | |||

| mm | inch | Size(mm/inch) | Thickness(mm) | Height(mm) | |

| 105 | 4” | 16/22.23 | 5/8”,7/8”,M14 | 6 | 16 |

| 115 | 4.5” | 16/22.23 | 5/8”,7/8”,M14 | 6 | 18 |

| 125 | 5” | 16/22.23 | 5/8”,7/8”,M14 | 7.5 | 18 |

| 150 | 6” | 16/22.23 | 5/8”,7/8”,M14 | 7.5 | 18 |

| 180 | 7” | 16/22.23 | 5/8”,7/8”,M14 | 8 | 18 |