Stone engraving is an age-old art form that has evolved significantly over the years, thanks to advancements in technology. One critical component in the stone engraving process is the drilling bit, which determines the precision, speed, and efficiency of the engraving. In recent times, vacuum brazed stone engraving bits have gained prominence for their exceptional performance and versatility. In this article, we will explore the comprehensive details of vacuum brazed stone engraving bits, shedding light on their construction, benefits, and applications.

1. Understanding Vacuum Brazed Stone Engraving Bits:

Vacuum brazed stone engraving bits are cutting tools used to etch intricate designs, letters, patterns, or images onto various types of stones, including granite, marble, sandstone, and limestone. These bits are meticulously designed and constructed to provide precise and controlled engraving, enabling artisans, sculptors, and stone craftsmen to achieve intricate detailing with ease.

2. Construction and Working Principle:

Vacuum brazed stone engraving bits are manufactured by brazing diamond particles onto the surface of a metal shank using a vacuum brazing process. This bonding technique ensures a robust and durable connection between the diamond particles and the shank, making the bits highly resistant to wear and tear.

The diamond particles on the surface of the bit serve as the cutting edges. Their exceptional hardness and abrasion resistance allow them to penetrate and carve through even the toughest stones. The vacuum brazing process eliminates the need for additional adhesives, ensuring the longevity and stability of the bits during high-speed engraving.

3. Advantages of Vacuum Brazed Stone Engraving Bits:

3.1 Superior Cutting Performance:

Vacuum brazed stone engraving bits offer exceptional cutting performance due to the high-quality diamond particles securely bonded to the shank. This enables precise and smooth carving, even on hard stones, reducing the need for manual touch-ups.

3.2 Versatility:

These bits are versatile and can be used on various types of stones, including granite, marble, sandstone, and limestone. Their ability to work with different stone materials makes them ideal for a wide range of applications, such as monuments, architectural features, memorials, and decorative pieces.

3.3 Increased Efficiency:

Vacuum brazed stone engraving bits exhibit excellent heat dissipation properties due to the vacuum-brazed diamond particles. This feature allows for continuous cutting without overheating, leading to increased efficiency and reduced downtime during the engraving process.

3.4 Extended Lifespan:

The vacuum brazing technique ensures a strong bond between the diamond particles and the shank, resulting in an extended lifespan of the engraving bits. This longevity reduces the frequency of tool replacements, resulting in cost savings over time.

3.5 Easy Maintenance:

Maintaining vacuum brazed stone engraving bits is relatively straightforward. Regular cleaning and lubrication help remove debris and ensure smooth cutting. Additionally, periodically inspecting the bits for wear and tear allows for timely replacements, ensuring consistent engraving quality.

4. Applications of Vacuum Brazed Stone Engraving Bits:

The exceptional performance and versatility of vacuum brazed stone engraving bits make them invaluable tools for various applications, including:

4.1 Monuments and Memorials:

These bits enable the creation of intricate and detailed engravings on monuments and memorials, allowing for personalized messages, names, dates, and symbols to be etched onto stone surfaces.

4.2 Architectural Details:

Vacuum brazed stone engraving bits are used in the creation of architectural features like column capitals, friezes, and decorative motifs on building facades, providing an elegant and refined finish.

4.3 Artistic Sculptures:

Artists and sculptors use these bits to carve stunning sculptures and artistic pieces out of stone, achieving intricate details and textures that enhance the beauty of their creations.

4.4 Customized Stone Signage:

The precision and accuracy of vacuum brazed stone engraving bits make them perfect for crafting customized stone signage, ensuring clear and durable lettering for commercial or residential purposes.

Vacuum brazed stone engraving bits have revolutionized the art of stone engraving, offering superior cutting performance, versatility, increased efficiency, extended lifespan, and easy maintenance. Whether it’s creating monuments, architectural details, sculptures, or custom signage, these bits provide artisans and craftsmen with the tools they need to achieve intricate and captivating stone engravings. With their remarkable capabilities, vacuum brazed stone engraving bits continue to inspire creativity and push the boundaries of stone engraving artistry.

1. Precision and Detailing:

Vacuum brazed stone engraving bits are known for their ability to create intricate designs and precise detailing on stone surfaces. The diamond particles bonded to the shank provide exceptional sharpness and hardness, enabling artisans to achieve fine lines, delicate patterns, and intricate textures with remarkable accuracy.

2. Speed and Efficiency:

Thanks to their cutting-edge design and high-quality diamond particles, vacuum brazed stone engraving bits offer impressive cutting speeds and enhanced efficiency. The combination of sharp cutting edges and efficient heat dissipation allows for continuous engraving without the need for frequent interruptions due to overheating or tool wear.

3. Compatibility with Various Stone Types:

Vacuum brazed stone engraving bits are compatible with a wide range of stone materials, making them versatile tools for stone engraving applications. Whether you’re working with granite, marble, sandstone, limestone, or other types of stones, these bits can effectively carve through the material, delivering consistent results.

4. Reduced Chipping and Breakage:

One of the significant advantages of vacuum brazed stone engraving bits is their ability to minimize chipping and breakage during the engraving process. The strong bond between the diamond particles and the shank provides excellent stability, reducing the risk of damage to the stone and ensuring clean and precise cuts.

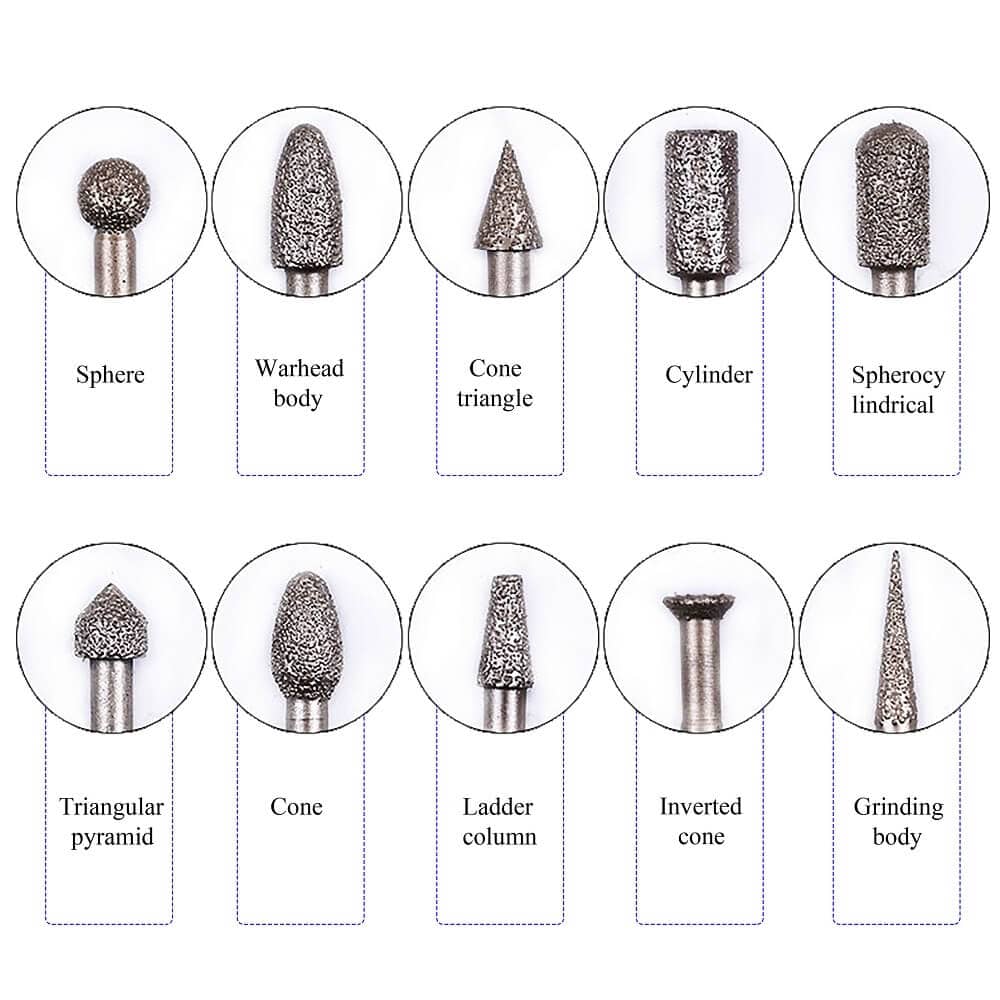

5. Wide Range of Bit Shapes and Sizes:

Vacuum brazed stone engraving bits come in a variety of shapes and sizes to accommodate different engraving needs. Common shapes include cylindrical, conical, ball-shaped, and flame-shaped bits. The availability of various sizes and profiles allows artisans to choose the most suitable bit for their specific engraving requirements, ensuring optimal results.

6. Longevity and Cost-Effectiveness:

Due to their robust construction and durable diamond bonding, vacuum brazed stone engraving bits have an extended lifespan compared to conventional engraving tools. This longevity translates into cost savings as there is reduced downtime and fewer replacements needed over time, making them a cost-effective choice for professionals in the stone engraving industry.

7. Compatibility with Engraving Machines:

Vacuum brazed stone engraving bits are designed to be compatible with various types of engraving machines, including CNC routers and handheld engraving tools. This compatibility allows for seamless integration into existing workflows and provides flexibility for different engraving projects.

8. Safety Considerations:

When using vacuum brazed stone engraving bits, it is important to prioritize safety. Always wear appropriate personal protective equipment (PPE) such as safety goggles and gloves to protect yourself from any potential hazards. Additionally, ensure proper ventilation in the workspace to minimize exposure to dust and debris generated during the engraving process.

By harnessing the capabilities of vacuum brazed stone engraving bits, artisans and craftsmen can elevate their stone engraving projects to new heights, unlocking a world of creativity and precision. Whether it’s crafting intricate designs, embellishing architectural details, or creating unique stone sculptures, these bits provide the tools necessary to transform stone into captivating works of art.

Stone Engraving Bits Specifications

|

Product name

|

Diamond Tool Carving Stone Diamond Engraving Grinding Bit For Engraving Machine CNC Carving Tool

|

|

Technology

|

Vacuum brazed

|

|

Purpose

|

Grinding Shaping Stone

|

|

Grit size

|

As your requirement

|

|

Material

|

Diamond, Metal

|

|

Shape

|

Flat, Dish, Bowl, can be customized

|

|

Application

|

Dry/wet grinding for granite, stone, concrete

|

|

Technology

|

vacuum brazed

|

|

Applicable Machine

|

CNC Milling Machine

|